Process Monitoring for Advanced Manufacturing

Laser Cladding & DED

Automation Acoustics technology is detecting sub-surface faults in laser cladding processes.

Thermal Spray

Our acoustic analysis platform is being used to identify nozzle blockages and other faults in thermal spray processes.

Wire Arc Additive Manufacturing

The addition of acoustic monitoring has enabled early fault detection in wire arc additive manufacturing.

Acoustic Monitoring

The missing piece of Industry 4.0

Every process, every fault emits a unique sound.

Correlating specific sounds with critical faults enables real-time corrective action.

- A Digital Twin generated from acoustic data visualizes where and when process non-conformance occurs.

- With the right technology, enclosed Advanced Manufacturing cells are a rich source of process knowledge.

- Acoustics are high resolution / low data intensity, enabling a complete process understanding.

Acoustics are your competitive advantage.

Integrate Digital Acoustics for Productivity

Capability

Informed decision-making

Enhance digital skills

Translate knowledge into procedures

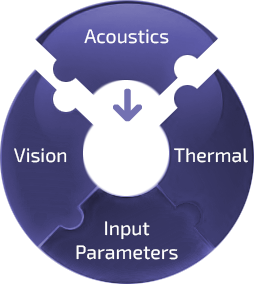

“Monitor the process, not only the input parameters”

Sustainability

Increase production yield

Prevent product to scrap

Reduce uncontrolled process variation

“Skilled team members know when the process sounds right”

Productivity

Interactive Digital Twins

Minimize the cost of Quality

Continuously improving Machine Learning models

Combine Continuous Improvement with Digital Transformation

3 steps to competitive advantage with Automation Acoustics...

1. Feasibility

Correlate acoustics with the specific issues that impact production quality.

2. Calibration

Customise proprietary algorithms to consistently identify the specific issues.

3. Integration

Implement real-time & digital twin capabilities that enhance productivity.